|

The plants offered by Buildmate incorporate aggregate hoppers which are in-line and can be placed at right angle to the inclined conveyor or in-line with it. These structures are manufactured from high quality steel sections to immaculate dimensional accuracy and finish. Weigh conveyor is located under the aggregate hoppers, which is slung on load cells. The sequentially batched material is accurately weighed on this conveyor. The weighed material then moves on to the inclined conveyor. The load cells and pneumatic actuators fitted to the hopper gates which are controlled by the control station. |

|

|

|

The inclined conveyor is positioned at an angle of 28 degrees connecting the weigh conveyor discharge point and the entry point at the mixer or the holding hopper. There by creating stock of a batch above the mixer, this feature enhances productivity considerable on plants such 90 cu.m / hr and above. The conveyor is covered by a hood in order to avoid dust contaminating the environment. |

|

|

|

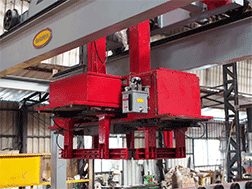

This picture shows the placement of the holding hopper and the cement, water and admix weigh hoppers placed over the twin shaft mixer. Also the discharge hopper of the mixer is shown, to which the transmit mixer will engage for transporting concrete. |

|

|

|

Our mixers are controlled hydraulically and are equipped with necessary electronics to ensure smooth start and long service life. They need very little routine maintenance. |

|

|

|

A control cabin installed at the job site. In this control cabin electrical panel is housed which contains all the electrical switch gear, control circuit software and the HMI which enables the operator to operate the entire plant effortlessly. |

MIXERS

MIXERS PRE ENGINEERED BUILDINGS

PRE ENGINEERED BUILDINGS SPECIAL PROJECTS

SPECIAL PROJECTS  AAC PLANTS

AAC PLANTS  STONE CRUSHING PLANTS

STONE CRUSHING PLANTS CONCRETE BATCHING PLANTS

CONCRETE BATCHING PLANTS DRY MIX MORTAR PLANTS

DRY MIX MORTAR PLANTS PRECAST CONCRETE PLANTS

PRECAST CONCRETE PLANTS CONCRETE BLOCK / BRICK PLANTS

CONCRETE BLOCK / BRICK PLANTS CRANES

CRANES