AAC Block Machinery Manufacturers & Making Plant

Cellular concrete is a construction material that has been developed in Europe. It is being quickly adopted for us in India, Middle East and other developing countries too. The most common and widely accepted type of cellular concrete is the Aerated concrete blocks. They are also called as Gasbeton, and sand lime bricks in different locations and based on the raw materials used

Aerated Autoclaved Concrete or AAC Block Machinery Manufacturers are very light weight blocks which are still strong enough for most applications. They are easy to install, cut and drill for various construction purposes and consume less cement and plastering material. They are a valuable new construction material for the modern times as they are light and strong and easy to use. They are excellent substitute to conventional bricks as they have low moisture absorption, high heat and fire resistance and effective sound absorption.

The individual block units are also comparatively large and stay true to their intended shape and size. Along with their considerably light weight they ensure rapid construction as more wall is laid per man hour than any other material.

AAC blocks by Buildmate Projects Pvt Ltd is one of the leading AAC Block Machinery Manufacturers and suppliers of the best quality AAC blocks products.

AAC Blocks, Autoclaved aerated concrete blocks is made up of fine Aggregates, Cement, and Expansion Agent

The IS:2185 code praises the attractive appearance of these blocks which are readily adaptable for any style of architecture as they allow a wide variety of surface finishes for exterior and interior walls. This governmental document even recommends not using plaster with such AAC blocks for unimportant buildings in low rainfall areas as they have true plane surfaces.

They can be used for both load bearing and non-load bearing internal walls. They are great for partition and panel walls as well as external load-bearing walls and even panel walls in steel or reinforced concrete frame construction.

| Flyash / Sand | 75 % |

| Cement | 12-15 % |

| Gypsum | 1-2 % |

| Lime | 7-9 % |

| Alumina | 400-500 g per cu.m |

| Water |

Advantages of AAC blocks:

- Light weight blocks

- Eco-friendly material

- Considerable savings in mortar

- Greater sound insulation

- Greater fire resistance

- Quicker construction

- Higher overall savings

Comparison of conventional blocks with AAC blocks:

|

Properties |

Burnt Clay Brick |

Concrete Blocks |

AAC Blocks |

|

Dry Density (kg/m3) |

1800-2000 |

1700-2000 |

450-1000 |

|

Compressive strength |

30-80 |

30-150 |

30-60 |

|

Block Size |

229x114x70 |

400x200x200 400x200x150 400x200x100 |

L: 600/500/400 W: 100/150/200/250 H: 200/250/300 |

|

Thermal conductivity |

0.7 |

1.1 |

0.21 – 0.42 |

|

Sound Insulation |

Normal |

Good |

Best |

|

Ease of use |

Normal |

Hard |

Easiest |

|

Environmental friendliness |

Poor |

Normal |

Green |

MIXERS

MIXERS PRE ENGINEERED BUILDINGS

PRE ENGINEERED BUILDINGS SPECIAL PROJECTS

SPECIAL PROJECTS  AAC PLANTS

AAC PLANTS  STONE CRUSHING PLANTS

STONE CRUSHING PLANTS CONCRETE BATCHING PLANTS

CONCRETE BATCHING PLANTS DRY MIX MORTAR PLANTS

DRY MIX MORTAR PLANTS PRECAST CONCRETE PLANTS

PRECAST CONCRETE PLANTS CONCRETE BLOCK / BRICK PLANTS

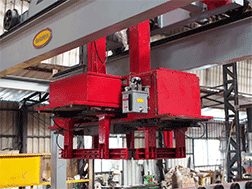

CONCRETE BLOCK / BRICK PLANTS CRANES

CRANES